In the vast world of industrial projects, every bend and curve matters. Whether it’s constructing pipelines for oil and gas, fabricating parts for machinery, or crafting intricate frameworks for buildings, the precision of tube bending plays a pivotal role.

Let’s dive into the reasons why professional tube bending stands as a cornerstone in the success of industrial endeavors.

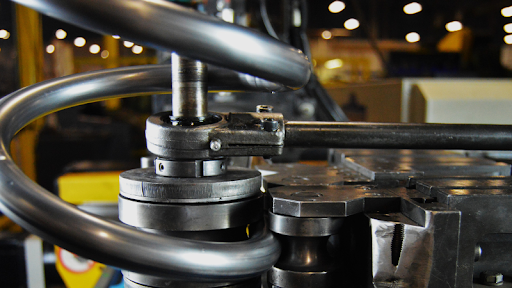

Precision Matters in Every Bend

When it comes to industrial projects, precision is paramount. A single deviation from the required angle or radius in tube bending can lead to costly errors and compromises in functionality. Professional tube bending ensures that each bend is executed with utmost accuracy, meeting the exact specifications of the project.

This precision guarantees seamless integration of components and enhances the overall efficiency and reliability of the end product.

Enhanced Structural Integrity

Industrial projects often involve the transportation of fluids, gases, or structural loads through pipelines and frameworks. The integrity of these structures is non-negotiable, as any compromise can result in catastrophic consequences.

Professional tube bending techniques, backed by years of expertise and advanced machinery, ensure that the integrity of the tubes remains uncompromised.

Optimized Performance and Functionality

In the realm of industrial projects, performance and functionality are key determinants of success. Whether it’s maximizing the flow of fluids through a pipeline or optimizing the efficiency of a machine, every component must perform at its peak.

Professional tube bending facilitates the creation of custom bends and configurations tailored to the specific requirements of the project.

Cost-Efficiency Through Waste Reduction

In any industrial project, efficiency and cost-effectiveness go hand in hand. Wastage of materials not only adds to the project’s expenses but also impacts environmental sustainability. Professional tube bending minimizes material wastage by precisely bending tubes to the required specifications, eliminating the need for excess trimming or corrections.

By reducing waste and optimizing material utilization, professional tube bending contributes to cost-efficiency while minimizing the project’s environmental footprint.

Adaptability to Diverse Applications

Industrial projects span a wide range of sectors, each with its own unique requirements and challenges. From aerospace engineering to automotive manufacturing, the versatility of professional tube bending allows it to cater to diverse applications with ease.

Whether it’s bending tubes of different materials, sizes, or shapes, professional tube bending can adapt to the specific needs of each project, ensuring seamless integration and functionality across various industries.

The Role of Hard Money Loans in Funding Industrial Ventures

In the realm of industrial projects, funding plays a crucial role in driving innovation and progress. Hard money loans serve as a lifeline for entrepreneurs and businesses looking to embark on ambitious industrial ventures.

Unlike traditional bank loans, hard money loans offer flexibility and accessibility, enabling swift acquisition of funds without the stringent requirements of conventional financing options.

Conclusion

In the intricate tapestry of industrial projects, professional tube bending emerges as a linchpin that holds everything together. From ensuring precision and structural integrity to optimizing performance and functionality, professional tube bending plays a multifaceted role in driving the success of industrial endeavors.

As industries continue to evolve and innovate, the importance of professional tube bending remains undeniably essential, serving as a cornerstone for progress and excellence in the industrial landscape.